Automation Training Zone

Article Index

Zone Highlights

Precision Motion Control

Motion control often involves twin demands of increasing speed and precision. As speed impacts productivity, it is an area of much interest. Improvement of the machine efficiency generates immeasurable added value, including reduction of labour and the machine floor area for the same quantity of production. But, when machine speed increases, a problem with the stop precision is often generated. In order to resolve this challenge, diversified grades of position controllers have been developed and used. It is easy to visualize through the difference of accuracy offered by positioning using Induction motor with limit switch controlled and same as using AC drives with highly sophisticated Motion Controllers.

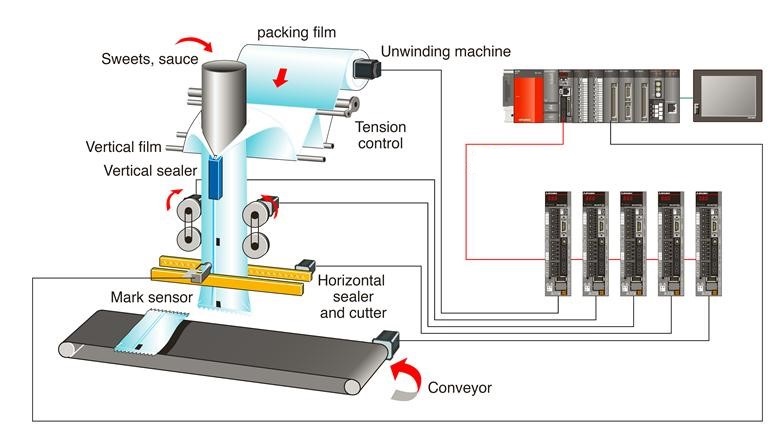

In modern machines, AC servo systems with features like synchronization with multiple moving axes – rotary or linear, electronic CAM and on the fly CAM generation, deliver low footprint compared to delivery capacity, maximum positioning accuracy like 10-4 degree of rotation, advanced control methodology like auto-tuning, vibration adaptive filters etc. They are the emerging actuation systems for optimum productivity for today’s manufacturing.

This training module covers basics of AC servo, positioning feedback element likes Encoders, homing methods, selection of AC Servo and Controller, identification of elements of servo systems, and interfacing with controller and HMI. It also includes hands on practice of different positioning instructions, synchronous control, CAM creation and implementation using training cum demo setups.

Attendees' profile

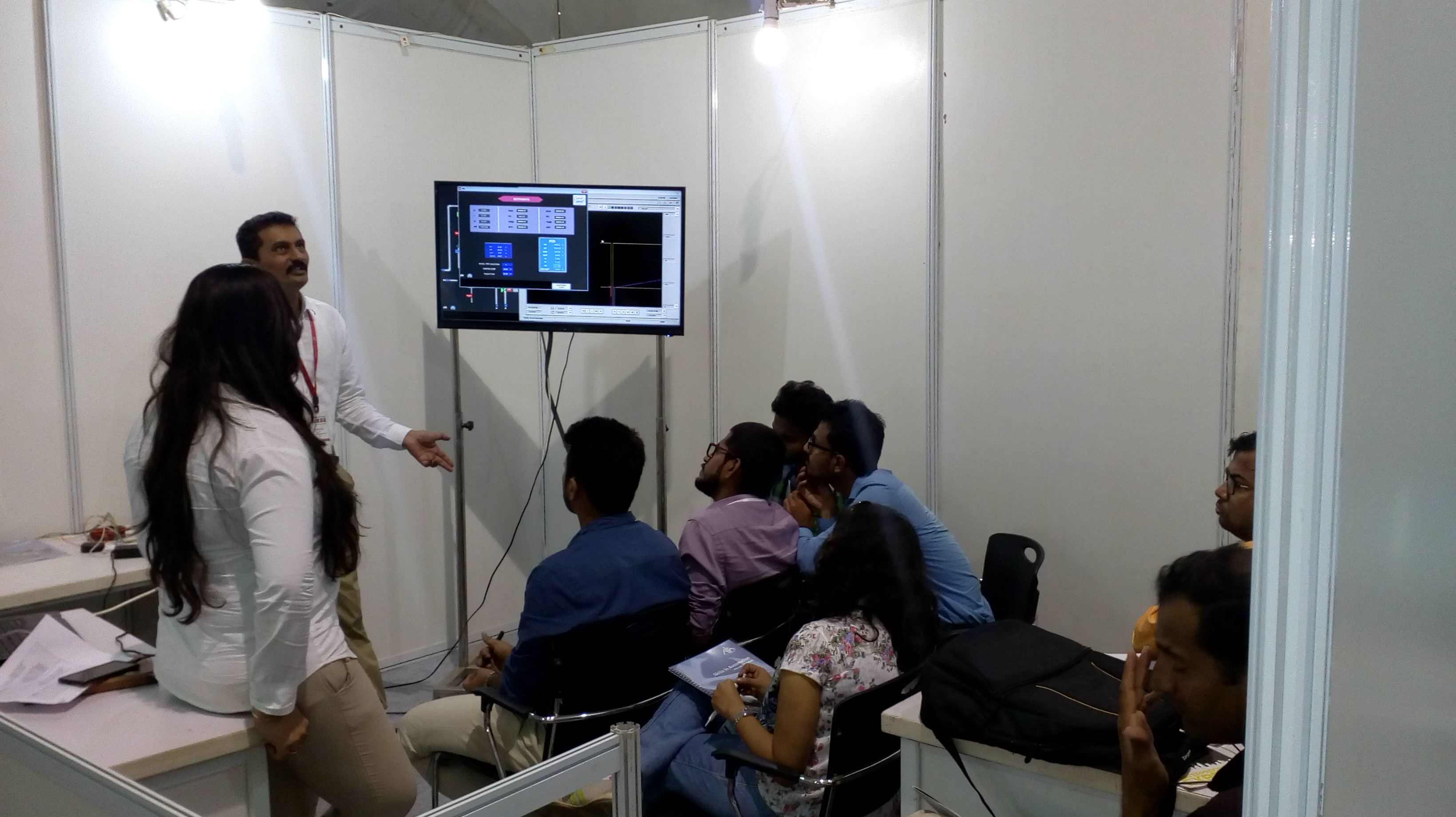

Team members with minimum one year of experience in handling industrial equipment with knowledge of PLC system, programming of PLC and basic knowledge of servo system from System Integrators of Factory Automation and project engineer, OEM from Automotive, Metal, F&B, FMCG, Pharma, Packaging, Plastic, Textile, and technical personnel responsible for system design, selection of servo system and engineering attended the session.

Equipment presented for Hands-on /Demo

Demo cum exercise station set-up at show, consisted of latest Servo Systems (Drives & Servo Motor), Servo Controller and PLC.

Participants received following benefits

- Understanding the needs of AC Servo & terminology

- Overview of AC Servo Control system elements and its interfacing

- Components of Positioning profiles and correlation to applications.

- Electronic CAM, different types, configuration and implementation

Lead Facilitator

- Mr. Rameshchandra Bhorania holds Master’s Degree (Systems & Control) from IIT, Mumbai.

- He has total experience of 19 years in the field of Automation includes maintenance, projects and training.

- Presently he is working with Mitsubishi Electric India, as Assistant General Manager – FA Training, responsible for FA product training, educational collaboration activity and also takes care of Technical support for CLPA to promote the CC link network in India.

FSM Faculty & Trainees from HAL Bangalore at the IITD Hauz Khas Campus

FSM Faculty & Trainees from HAL Bangalore at the IITD Hauz Khas Campus