Automation Pavilion

Article Index

Packaging 4.0 - India Perspective

27-30 July 2016, New Delhi

Pack Plus Exhibition at Hall 12 A Stall 40, Pragati Maidan, New Delhi.

Packaging machines are a vital part of the production process in the consumer goods industry. They often work in multi-shift operation, and any malfunctions have to be met with a fast response. Packaging 4.0 is an open forum for the Indian Packaging Machinery Suppliers and End Users.

Packaging 4.0 – India Perspective represents the shift towards new wave automation technologies that provide clear diagnostic and remedial strategies.

At the AIA Pavilion, Automation leaders, showcased and spoke about the HOT TOPICS that Indian machine builders and buyers of integrated lines are concerned with.

Automation Pavilion Highlights

| Theme Sponsor | Theme Sponsor | Supporting Partner |

|

About AIA - the Knowledge Partner

Automation Industry Association (AIA) founded in 2004, is India’s apex automation industry body, with nearly 40 high tech automation companies. It has pioneered the Integrated Automation approach in the Educational Curriculum for Universities and is also promoting Integrated Automation Practices and Skills consonant with emerging global trends. Packaging 4.0 is an open forum for the Indian Packaging Machinery Suppliers and End Users.

| Technology Partners | About the Partner | Highlights |

|

Theme Sponsor

|

The pioneering spirit of company founders Erwin Bernecker and Josef Rainer – and their vision of contributing something exceptional to the automation industry – sparked a fire that continues to shape our company to this day The pioneering spirit of company founders Erwin Bernecker and Josef Rainer – and their vision of contributing something exceptional to the automation industry – sparked a fire that continues to shape our company to this day. Keen foresight and entrepreneurial courage helped B&R rise quickly into the ranks of top global players in industrial automation..........Read More |

|

|

|

||

|

OMRON uniquely combines its full range of control components with the application know how and support necessary to build and maintain sophisticated automation systems. In manufacturing, benefits span all facets of the production process, including inventory and production control, communication networks, discrete manufacturing, quality control and integration, plant wide management and distributed information and control systems......Read More |

|

|

|

|

||

|

Supporting Partner

|

Menzel Vision & Robotics, is a one point source for not only world-class complete Imaging Solutions but also for separate components to integrate a solution. We offer proven solutions for Image Monitoring, Processing and Analysis needs like Automatic Machine Vision Systems, Robotic Machine Vision Software, Inspection Machine Vision Systems, Open Source Machine.....Read More |

|

Pavilion Highlights

Next generation Automation

Changing consumer demands are driving the evolution of packaging industry. Today, packaging machines need to handle smaller batches and help increase throughput, reduce downtimes. These machines are expected to be extremely flexible and fully automated. Therefore next generation automation will only help us to hide the complexity and provide better diagnostics with ease of operation.

B&R has introduced new technologies like web based diagnostics, new HMI concepts and IoT enabled controls which can bring enormous benefits to the machine builders and users alike.

Lead Facilitator

Name: Ritesh Raka

Brief Introduction

Mr. Raka has vast experience in industrial automation particularly application engineering and sales.

He is currently responsible for B&R's OEM sales for the North Indian region serving as Branch Manager - Delhi Region at B&R Industrial Automation Pvt. Ltd.

Pavilion Highlights

Flexible Manufacturing

To be faster to the market is a key to success in the competitive packaging industry. Flexible packaging lines will help reduce cycle times for the new product introduction and even allow batch size 1 in a continuous production. Factories will be highly integrated but more and more processes will be decentralized. This can be achieved with a strong foundation of scalable control system. B&R's APROL process control system satisfies the requirements of flexible and modular process manufacturing plants without neglecting the high demands on availability and data consistency.

In APROL, parameters such as overall equipment effectiveness (OEE) can be viewed at any time and even compared between production lines, shifts or workdays

Lead Facilitator

Name: Vijay Goyal

Brief Introduction

Mr. Goyal has experience in project engineering and commissioning.

He is currently responsible for B&R's product and solution sales for the North Indian region serving as Engineer - User Sales at B&R Industrial Automation Pvt. Ltd.

Pavilion Highlights

Open & Smart HMI

Over the last few years Open HMI has been at the forefront of industrial automation and operations management delivering companies the solutions and products they need to stay competitive and achieve business goals.

Open HMI was founded on the premise that industrial automation visualisation should be built on open technologies and enable the free flow of data beyond the control room. Products should be easy to implement and cost effective.

With a host of features to choose from you only need to purchase what is relevant to your project. With open HMI you can connect to and share data amongst a huge range of data sources and destinations. Connect to a variety of data sources such as OPC Servers, OPC Clients, Databases & variety of controllers .

Lead Facilitator

Name : Harish Kumar Sandesh

Brief Introduction:

Mr. Sandesh has more than 11 years of experience in field of Industrial Automation and has worked with Schneider Electric & Rockwell Automation.

He is currently Section Manager - Application Engineering & Customer Service at Omron Automation Pvt. Ltd.

Pavilion Highlights

Vision Guided Robotics

Lately there has been a convergence of vision with robotics – cameras are increasingly becoming the eyes of the robots so that they can be used to do complex tasks such as object tracking-identification-segregation. Vision Guided Robotics are being used in the industrial domain as it gives them more power than the proximity sensors and other sensors that helped the robots in not being blind in their various operations. Vision is being deployed in service robots and autonomous robots that are being used to fetch –carry and dispense raw materials at various production locations in the factory. Reversely robots are being integrated with vision systems for faster and accurate handling of the items to be inspected – helping one camera take images at different faces and angles of the objects being inspected that eliminates the need for multiple cameras; also for ensuring perfect positioning and alignment of the industrial camera vis-a-vis the various faces of the component to be inspected.

Robots integrated with vision are being increasingly used for track and trace in pharma industry – for automotive parts inspection for gauging / missing operation – packaging industry for completeness – FMCG and F&B industry for verification of shape size, quality and quantity while packaging. Robotic palletizing/depalletizing systems offer a smaller footprint and greater precision than conventional case packers, allowing these systems to address end-of-line needs for flexibility and versatility.

Lead Facilitator

Name: Anish Soneja

Brief Introduction:

Mr. Soneja is serving as Director at Menzel Vision and Robotics Pvt Ltd

Pavilion Highlights

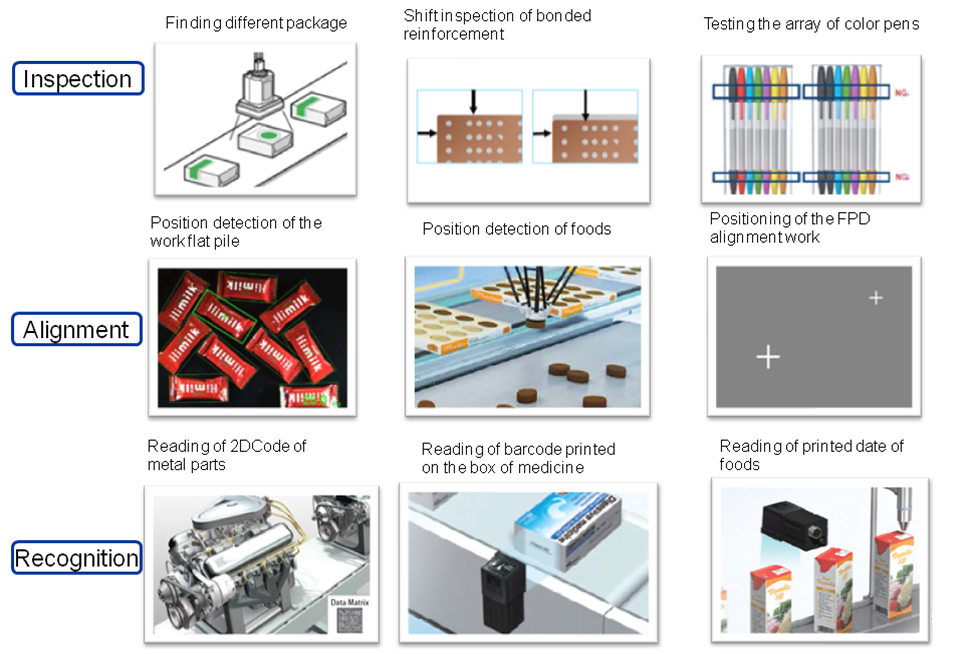

Vision System for Quality

In industrial production, the quality of an item is often inspected visually after the manufacturing process is finished. If this is done by humans, it takes a long time which makes it expensive.

The trend in the industry is to automate the visual quality inspection. This reduces material waste, product cost, and maximizes throughput.

For example, in automotive or pharmaceutical production, a 100% inspection is required. This is not practical with methods other than industrial image processing.

The vision system enables seamless in-process inspection. It helps to fix the problems at the outset and prevents common mistakes being repeated otherwise thus reducing the end-line defects. It saves time and efforts of final inspection and thus ensures the required quality of products in any given production line. Solutions for inspection of various defects and dimensional measurement with its vision inspection system are available . The multi camera inspection system ensures increase in line speed from 20 bpm to 150 bpm. It is a complete solution for defects and measurements with accuracy of 50 microns.

The primary uses for machine vision are automatic inspection and robot guidance. Common Vision System applications include quality assurance, sorting, material handling, robot guidance, and optical gauging.

Lead Facilitator

Name : Harish Kumar Sandesh

Brief Introduction:

Mr. Sandesh has more than 11 years of experience in field of Industrial Automation and has worked with Schneider Electric & Rockwell Automation.

He is currently Section Manager - Application Engineering & Customer Service at Omron Automation Pvt. Ltd.

Pavilion Highlights

Campus Connect

Blended learning, the teaching practice that combines teaching methods from both face-to-face and online learning, is an established, rapidly growing instructional model that is proving highly effective in helping institutions address the challenges of limited resources and the expectations of 21st century learners. Whether it is extending classroom instruction beyond the normal hours, supporting credit recovery programs, enhancing teacher professional development or delivering enriched learning opportunities for accelerated students, blended learning models are increasingly common practice across the curriculum for students and teachers alike.

Blended learning is implemented in a variety of ways, ranging from models in which curriculum is fully online with face-to-face interaction in laboratory sessions, to models in which face-to-face classroom instruction is integrated with online components. The rapid growth of blended learning has been a catalyst for additional instructional transformation, including:

1. Evolving pedagogy in which teachers’ roles include facilitation, student mentoring and differentiating instruction for individual learners,

2. Increased flexibility and personalization of students’ learning experiences

3. Strategic uses of technology as colleges tap the capabilities of the learning management systems to support a wider range of instructional programs.

The intent of AIA Campus Connect programme is to showcase this blended learning model’s potential and ignite faculty and students with new conversations about Integrated Automation learning and relevance to career needs in Industry.

Lead Facilitator

Name:Rachit Agrawal

Brief Introduction:

Mr. Agrawal is an engineering graduate from Jaipur National University in Electronics & Communication Department.

He is currently Program Executive at Automation Industry Association.

FSM Faculty & Trainees from HAL Bangalore at the IITD Hauz Khas Campus

FSM Faculty & Trainees from HAL Bangalore at the IITD Hauz Khas Campus